PRINCIPLES OF YARN CLEARING /YARN CLEARING IN WINDING / ASSESSMENTS OF CLEARER PERFORMANCE

Objective of yarn clearing -

Objective of yarn clearing is to remove objectionable faults from the yarn / supply package

Principles of measurement of yarn faults/Yarn diameter

Two principles are used in morden winders for identification of yarn faults

1. Capacitance principle

2.Optical principle

1.Capacitance principle -

Assessment of clearer performance

The performance of yarn clearer is assessed by two parameters

1.Clearing efficiency

2.Knot factor

1. Clearing efficiency -:

Clearing efficiency is defined as number of objectionable fault removed by yarn clearer express as a percentage of total faults present in a yarn before clearing .

Clearer efficiency -:

No of objectionable faults remove ×100

Total no of objectionable faults in yarn

2.Knot factor -:

Knot factor is the ratio of total number of yarn clearer related to breaks to no of objectionable faults removed

Knot factor =

Total number of yarn clearer realted to break

Number of objectionable faults removed

Note -:

Cleaning efficiency ideally should be 100% and knot factor Ideally should be 1

Objective of yarn clearing is to remove objectionable faults from the yarn / supply package

Principles of measurement of yarn faults/Yarn diameter

Two principles are used in morden winders for identification of yarn faults

1. Capacitance principle

2.Optical principle

1.Capacitance principle -

Working Principle- :

When yarn pass through two capacitor parallel plate the electrical signal changes / produce which is proportional to change in mass per unit length.

Working -:

In the capacitor electronic yarn clear device is measurement of yarn mass per given test length

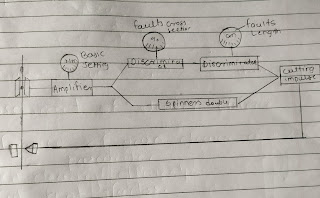

Any change in mass of yarn then the set value to makes corresponding change in a capacitance. The signal is send to the amplifier. The amplifier amplifies the signal and compared with previously set value in the discriminator . If the limit is goes above the set value then impulse is give to the cutter to cut the yarn faults is then remove and it's replace by knot or splice .

Expression for capacitor is

C = εA / d

Where, A= overlapping area of plate

d = distance between plates

ε = Permittivity of medium

Permittivity of vaccum is 8.85 × 10^-12 F/M

When the yarn is pass through parallel plates the equation =

C= A

Expression for capacitor is

C = εA / d

Where, A= overlapping area of plate

d = distance between plates

ε = Permittivity of medium

Permittivity of vaccum is 8.85 × 10^-12 F/M

When the yarn is pass through parallel plates the equation =

C= A

[(d1/ε1) +(d2 /ε2) ]

C= A

[(d1/k1) + (d2 /k2) ]

Where, d1= thickness of yarn

d2 = thickness of air

ε1 = permittivity of yarn

ε2 = permittivity of air

k1&k2 = dielectric constant

Note- Dielectric constant of water is 80

For textile material around 2 to 2.5

For air it's 1

Limitations / Disadvantage -

1. The capacitance will affect change in moisture content of material. Therefore any changes in humidity with respect to affect to the yarn clearing. It is very sensitive to moisture.

Name of capacitance clearer - Uster Quantum.

2.Optical principle -:

Working principle -:

The emitter emits the light and the receiver detect it and convert to proportional electrical signal. The light received by receiver will obviously depend on diameter of the yarn passing between emitter and receiver

Working -:

The optical type of clearer yarn is pass between light source and photocell,amount of light falling on photocell is set according to yarn count. Device measure the yarn diameter and yarn profile. If the amount of light fall on photocell changes beyond particular limit pulse is generated and fed to amplifier. The amplifier signal is then equate in discriminator. If the faults is objectional cutting impulse is generated

Note - 10% deviation in the yarn diameter will be equal to 21% deviation in the mass of yarn

Limitations /Disadvantage -

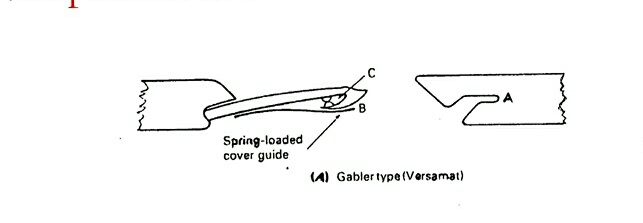

1. Sometimes flatten slubs can pass through

2. Deposition of dust and fly on the optical sensor is main cause

Name of optical clearer - Loepfe, optaphil, peyerfil. Yarnsepe

C= A

[(d1/k1) + (d2 /k2) ]

Where, d1= thickness of yarn

d2 = thickness of air

ε1 = permittivity of yarn

ε2 = permittivity of air

k1&k2 = dielectric constant

Note- Dielectric constant of water is 80

For textile material around 2 to 2.5

For air it's 1

Limitations / Disadvantage -

1. The capacitance will affect change in moisture content of material. Therefore any changes in humidity with respect to affect to the yarn clearing. It is very sensitive to moisture.

Name of capacitance clearer - Uster Quantum.

2.Optical principle -:

Working principle -:

The emitter emits the light and the receiver detect it and convert to proportional electrical signal. The light received by receiver will obviously depend on diameter of the yarn passing between emitter and receiver

Working -:

The optical type of clearer yarn is pass between light source and photocell,amount of light falling on photocell is set according to yarn count. Device measure the yarn diameter and yarn profile. If the amount of light fall on photocell changes beyond particular limit pulse is generated and fed to amplifier. The amplifier signal is then equate in discriminator. If the faults is objectional cutting impulse is generated

Note - 10% deviation in the yarn diameter will be equal to 21% deviation in the mass of yarn

Limitations /Disadvantage -

1. Sometimes flatten slubs can pass through

2. Deposition of dust and fly on the optical sensor is main cause

Name of optical clearer - Loepfe, optaphil, peyerfil. Yarnsepe

Assessment of clearer performance

The performance of yarn clearer is assessed by two parameters

1.Clearing efficiency

2.Knot factor

1. Clearing efficiency -:

Clearing efficiency is defined as number of objectionable fault removed by yarn clearer express as a percentage of total faults present in a yarn before clearing .

Clearer efficiency -:

No of objectionable faults remove ×100

Total no of objectionable faults in yarn

2.Knot factor -:

Knot factor is the ratio of total number of yarn clearer related to breaks to no of objectionable faults removed

Knot factor =

Total number of yarn clearer realted to break

Number of objectionable faults removed

Note -:

Cleaning efficiency ideally should be 100% and knot factor Ideally should be 1

Comments

Post a Comment