Rapier weft Insertion System

Repier Weft Insertion system -

The picking or weft insertion system is based on modified repair principle, two carriers entering the warp Shed simultaneously from each side of the loom and meeting almost half way through the shed. These are two basic type of rapier heads: 1) Loop transfer rapier machine-Gabler Principle , 2) Tip transfer repair machine -Dewas principle.

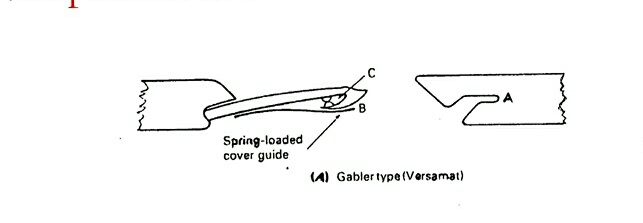

In the Gabler system the weft is never gripped. It is placed in a slot 'A' in the right rapier head and as the rapier advance towards the centre of the Loom, the yarn passes from its clamped position round the head, to the supply package in the form of hair pin .When the head meet at the centre of the loom, the smaller left hand head , enters the yarn carrying right hand head. The thread at 'A' is passed under the spring loaded cover guide at 'B' and as the left hand rapier is withdrawn,it repositions the weft at 'C'. The yarn then slides through the left hand repier head as it is withdrawn so that the hair pin is straightened out.

Dewas system as shown in figure yarn is gripped in each rapier heads. the gripping unit usually consists of fixed point against which is spring loaded clamp presses to trap the weft . The spring loaded clamp has a cam profile that meet a fixed point on the loom or sley . These points open the clamp when the weft is to be picked up or released outside the selvedge. The right hand thus clamps the weft at 'A' and pulls it through the shed until the heads meet at centre.

The thread is then guided round point 'B 'and as the left hand head withdraws the thread is trapped at 'C' and pulled across the loom to complete insertion .

Good make it comprencompre

ReplyDeleteGood job ;-)

ReplyDeleteNice content!

ReplyDelete