WINDING PROCESS

Object of Winding -

1. Conversion of small package into the bigger package (Ring bobbin into Cheese or cone having more yarn content than ring bobbin )

2. To provide the long continuous length of yarn in the form of cheese and cone.

3. To remove the objectionable fault in the yarn ( Objectionable faults in the yarn which is allow to the yarn,we reduce the fabric quality and or reduce machine productivity)

4. To prepare the compact package cheese or cone which we have uniform density throughout the package and unwind well in the next process.

BASIC PRINCIPLE OF PACKAGE WINDING

For package winding yarn can be withdrawn by two method

For package winding yarn can be withdrawn by two method

1. Side withdrawal

2. Over end and all nose withdrawal

2. Over end and all nose withdrawal

In the side withdrawal for unwinding the yarn,package is rotated.

In nose unwinding package is stationary when there is nose unwinding one coil come out one twist either added or subtracted from the yarn depending on twist in the yarn .

In nose unwinding package is stationary when there is nose unwinding one coil come out one twist either added or subtracted from the yarn depending on twist in the yarn .

DIFFERENT TYPES OF WOUND PACKAGE

1. Parallel wound package

2. Nearly parallel wound package

2. Cross wound package

1. Parallel wound package

2. Nearly parallel wound package

2. Cross wound package

PARALLEL WOUND PACKAGE -

In a parallel one package, yarn are laid parallel to each other.This help to to maximize the yarn content in the package. In parallel wound package suffers from problems of stability and layers of coil can collapse specially from two sides of the package.Therefore double flanged package are sometimes used for a parallel package.

Eg - Weavers beam , warper beam .

In a parallel one package, yarn are laid parallel to each other.This help to to maximize the yarn content in the package. In parallel wound package suffers from problems of stability and layers of coil can collapse specially from two sides of the package.Therefore double flanged package are sometimes used for a parallel package.

Eg - Weavers beam , warper beam .

NEARLY PARALLEL WOUND PACKAGE -

In nearly parallel package successive coil of yarn are made at very small angle. the rate of the traverse is very slow. This package give higher density and therefore content more yarn

CROSS WOUND PACKAGE

In cross package and yarn are laid the package at considerable angle. As the coil crosses each other every time. The package content is lower than that of the parallel wound package . However, cross wound package provide a very good package stability . Uniform density of the yarn laid on to the package.one of the advantage of this package is a self supporting package. No need any equipment to unwound the package.

SUPPLY PACKAGE OF WINDING

1. Mule - It is package having short and medium traverse length produce quick traverse. this former package is use woollen and worsted yarn.

2. Roving - Roving with has layers of parallel yarn to the spindle axis. As bobbin build of give the stability.Traverse is short .This type of package produce the filament industry.

3. Ring bobbin - In this uniform layer of yarn are laid conical base and the layers are gradually progress upward until is filled. This type of the bobbin is used in a cotton yarn

Hank - It is a bundle of yarn containing a certain length and can easily handle for transportation dyeing and bleaching.

END PACKAGES -

Warper bobbin -

In this package yarn wound in parallel to each coil. It has two flanges for support The barrel length is

12 to 17 CM .The flange circumference is 11.4 CM .The package will produced by slow traverse. The unwinding is side withdrawal, there for package is also rotated

In this package yarn wound in parallel to each coil. It has two flanges for support The barrel length is

12 to 17 CM .The flange circumference is 11.4 CM .The package will produced by slow traverse. The unwinding is side withdrawal, there for package is also rotated

Cheese-

It is cylindrical cross wound and self supporting package .The package traverse for fine count is 12-15 cm and for coarser count traverse length is 18-22cm . When the bobbin is unwinding the package is stationary.

It is cylindrical cross wound and self supporting package .The package traverse for fine count is 12-15 cm and for coarser count traverse length is 18-22cm . When the bobbin is unwinding the package is stationary.

Spool -

It is narrow cheese having traverse length is 7.5 cm .It is cross wound and self supporting package . This package use in barber cone machine.

It is narrow cheese having traverse length is 7.5 cm .It is cross wound and self supporting package . This package use in barber cone machine.

Cone -

Cone is self supporting package .The yarn is withdrawal from conical side.

It usually for warping, knitting and weft supply. The cone angle for different cone varies. It is angle between side and axis.

3° 30' for warping of all yarn

4° 30' for yarn wound stainless steel for dyeing process.

9°15' for knitting cone and synthetic yarn .

Cone is self supporting package .The yarn is withdrawal from conical side.

It usually for warping, knitting and weft supply. The cone angle for different cone varies. It is angle between side and axis.

3° 30' for warping of all yarn

4° 30' for yarn wound stainless steel for dyeing process.

9°15' for knitting cone and synthetic yarn .

Foster cone -

It is cone initial tapper is 9°15' and tapper is when the cone is full is 40°. It is use for knitting purpose, avoid the Slough off coil.

It is cone initial tapper is 9°15' and tapper is when the cone is full is 40°. It is use for knitting purpose, avoid the Slough off coil.

WINDING PARAMETERS -

1. Traverse Length -

The yarn is taken from left hand side of the package to the right hand side of the package to horizontally. This length is know as traverse length. It is also length between the two reversial point on package.

The yarn is taken from left hand side of the package to the right hand side of the package to horizontally. This length is know as traverse length. It is also length between the two reversial point on package.

2. Wind -

The number of wrap(or coil) of yarn wound with in traverse length is called wind .

3. Scroll -

Drums are manufacturer with different scroll

--.one scroll is one revolution of drum is required to complete one yarn traverse

The number of wrap(or coil) of yarn wound with in traverse length is called wind .

3. Scroll -

Drums are manufacturer with different scroll

--.one scroll is one revolution of drum is required to complete one yarn traverse

--1.5 scroll means the drum required 1.5 revolution to complete one yarn traverse.

Drums are made with 1 , 1.5 , 2, 2.5 scroll

Drums are made with 1 , 1.5 , 2, 2.5 scroll

3.Traverse ratio -

It is also as wind ratio or wind per double traverse .

It is number of revolution made by the package during time taken by the yarn guide to make to and fro traverse or double traverse.

Traverse ratio = 2× wind

It is also as wind ratio or wind per double traverse .

It is number of revolution made by the package during time taken by the yarn guide to make to and fro traverse or double traverse.

Traverse ratio = 2× wind

4. Angle of wound -

It is angle made by the yarn with the side of package..

It is angle made by the yarn with the side of package..

5. Coil angle -

It is what is the angle by the yarn with the axis of the package. The coil angle and angle of wind are complementary angle as they add upto 90°.

It is what is the angle by the yarn with the axis of the package. The coil angle and angle of wind are complementary angle as they add upto 90°.

TYPES OF WINDING MACHINE -

There are two type of winding machine are available

1. Drum winding machine

2. Precision winding machine

There are two type of winding machine are available

1. Drum winding machine

2. Precision winding machine

1) DRUM WINDING MACHINE -

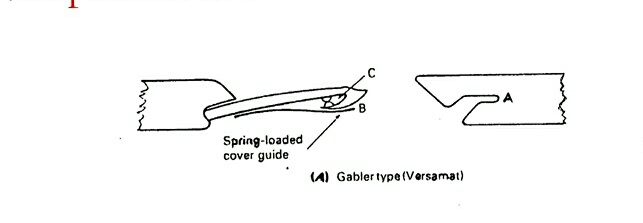

In the drum driven machine package rotated by cylinder due to the frictional contact. For cross winding the package we need to give a traverse to the yarn . This traverse is given by the good quote in the drum or by separate reciprocating guide guide

In the drum driven machine package rotated by cylinder due to the frictional contact. For cross winding the package we need to give a traverse to the yarn . This traverse is given by the good quote in the drum or by separate reciprocating guide guide

Comments

Post a Comment