Electronic Systems For Textile Testing/Yarn Evenness tester

Introduction

Textile testing always a essential part of production and use of processes, has become even more important in a recent year as a result of new demands placed upon the product of the textile manufacturers. Advancement in a technology has made a great impact on textile testing also. If you compare the conventional testing instrument with mordern testing instruments we will find a spectacular change in a testing instrument due to the application of electronic. Although use of electronic system has changed ,the whole scenario in textile but in fact on test instrument is amazing .All important fibre properties can be determined by the putting the fibre sample in high volume instrument within a few minutes by any person, otherwise it is used to take at least 5 - 6 hours and extensive skilled work by operators. Similarly by using various electronic system testing instrument have become so user friendly. that any body can be test for various properties.

Evenness testing -

The history of Electronic Evenness Testing goes back 50 years. Before this time mass variation in yarn,roving and sliver was determined either visually or by cutting and weighting equal length of fibre assemblies. This time consuming method of the measurement had a limitation particularly with respect to the shorter length and due to the Limited accuracy of the available balances. The variation between the cute lengths were than provided in the form of CV % values. Locher invented the first electronic evenness tester shortly after the conclusion of Second world war which was brought onvto the market by the Zellweger Uster Company in 1948. In 1950 Fielden and Walker also introduced a similar instrument. In year between 1940 and 1955 , therefore, the theoretical basis for evenness testing waa set out. In a following year testing Apparatus for the determining this characteristic were continuously improved both with respect to the there accuracy and also with respect to the evolution possibilities.

Working principle -

The measuring devices of Electronic Evenness Tester is parallel plate air capacitor .Under a certain condition the effect of introducing a non conducting material such as a sliver or yarn into the space between the plate is to changes the capacity of the capacitor .The change being proportional to the weight of the material present. If therefore the material is drawn through the capacitor continuously the change in a capacity will be follow the variation in the weight per unit length of the strand .The unit length being the length of the capacitor.Now it is necessary to sense the changes in a capacity and to translate them electronically into the such signal which is indicate the co-efficient of variation. At the same the time trace of the variation should be made on a pen recorder if required.

The design of the capacitor and associated electronic circuit is a subject in it self ,but some of the design problem should be appreciated and will be mentioned now before the actual instrument are described.

As we know ,the change in a capacity are linearly related to the weight of the material present, the material thickness should not exceed 40% of the distance between the capacitor plates ,hence to accommodate range of materials from sliver to fine yarn a series of interchangeable capacitor necessary.

Secondly ,the length of the capacitor should be as short as possible so that the variation in weight are measured over the short length. In the Fielden Walkar tester this length is 1 cm, and in the Uster it varies from 8 mm to 20 mm (for coarser material).

Secondly ,the length of the capacitor should be as short as possible so that the variation in weight are measured over the short length. In the Fielden Walkar tester this length is 1 cm, and in the Uster it varies from 8 mm to 20 mm (for coarser material).

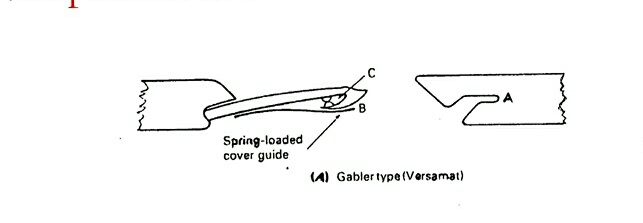

Thirdly ,the shape of cross section of the tested strand affects the change in a capacity. It is essential that the strand maintaind its shape during it passage through the capacitor. Where the soft material are tested ,guides are used which is slightly Compress the strand into the suitable form just before it enter the Capacitor. For spun yarn and the twist keeps the cross-section approximately circular Filament yarns with low twist require extra twist and so special twist tube, something like a false twister is used.

Another important part is moisture in material affect the magnitude of the change in a capacity, a higher moisture content giving a greater change in a capacity. In the Laboratory, therefore it is more important to ensure the moisture content in uniform throughout the sample.

The Uster Evenness tester -

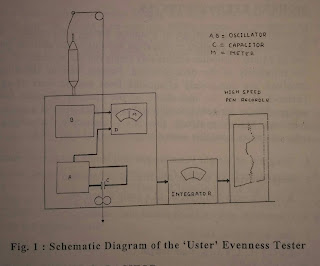

Schematic diagram of evenness tester is shown in figure

Two oscillators A and B have equal frequencies when there is no material in the measuring capacitor C. When the two frequency is superimposed difference in a frequency is zero.The presence of the material in a capacitor causes it's capacity to change and so alter the frequency of the oscillator A. There will be difference between the two frequencies witch varies according to the amount of material between the capacitor plates.Suitable circuit D translate is frequency differences into the signal which is which can indicate (1). The variation in meter M,(2) drive the pen of the recorder and (3) are fed into the integrator which indicates the average irregularity either as a percentage mean deviation or coefficient of variation. Modern Evenness tester can indicate both U% as well as CV%.

Good

ReplyDeletethank you for the efforts you have made in writing this article.

ReplyDeleteElectric bikes

Great info! I recently across your blog and have been reading along. I thought I would leave my first comment. I don’t know what to say except that I have. 500w e bike

ReplyDeleteWe are really grateful for your blog post. You will find a lot of approaches after visiting your post. I was exactly searching for. Thanks for such post and please keep it up. Great work. 55 inch smart tv

ReplyDelete