Sluzer Shuttleless Weaving Machine/ Working Of Projectile Mechanism

Sulzer Shuttleless Weaving Machine -

In this weaving machine, the weft yarn is introduced into the shed by means of a gripper.A tuck -in selvadge is formed by drawing the cut weft end into the shed by means of tucking needles. The pick is then beaten up by means of cam operated reed.

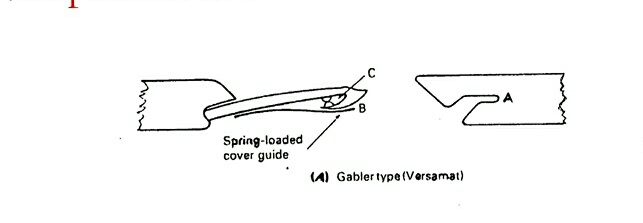

A torsion bar arrangement is used for propulsion of the gripper through the open shed.The gripper while travelling from left hand side to the right hand side is made up to follow a fixed path across the loom by means of a series of rake guides which is elevated into the shed before picking and again falls below the bottom shed line before beat up . The gripper on reaching the right hand side leaves the weft yarn ,falls down to conveyor underneath the sley and return back to the left hand side to follow to the cycle of picking .At a time only one gripper is picked in the shed and so gripper returns at much slower speed than the weaving speed,many gripper are in a circulation so that soon as one pick is picked another gripper should be ready for the next pick (17 gripper is 130" width loom and 13 in 85" loom; size of each group is 3. 5" ×0. 5" × 0. 24"weighing 1.33ozs).

After each pick, the weft is cut and tucked with the next shed at both selvedges. It is possible to provide similar tucked in selvedges for the intermittent fabric also. For every pick there will be double the density in the selvedges which which may be lead the difficulties in processing. In order to overcome this, finer warp yarn for the selvedges compared to the body warp end is used.

Comments

Post a Comment