Jet Weaving Machines

Jet Weaving Machine -

In this machines, weft yarn fed through the main nozzle is transported through the warp shed by the momentum imparted to it by jet of air or water blasting out of the nozzle .

Functional Elements of Jet looms -

- Weft feeding devices - weft accumulator , tensioners and stopper.

- Main nozzle

- Air guides and relay nozzles (only for air jet loom)

- Suction funnel for air jet looms and water collecting arrangement for water jet looms.

- Weft feeler

- Air distribution

Unlike in case of other shuttleless weaving machines, the length of the weft yarn to be inserted need to be measured accurately in each weft insertion cycle in jet weaving machines , because of the lack of physical control over it is not weft insertion process. Basically ,weft yarn measured by rotating feed rollers and stored in a storage tube before feeding or is wound on the accumulator drum .

Tensioners by imparting a light tension to the weft yarn ,when it is being measured, prevents it from snarling and the coils on the accumulator drum from stripping .

Stoppers holds the yarn tight after weft insertion and before beat up. It continues to hold it until the weft insertion is about to start in the particular main nozzle.

Main nozzle facilities withdrawal of weft from the weft accumulator , imports the initial momentum to the yarn and guides yarn into the weft insertion zone .

Air nozzle and Air guide -

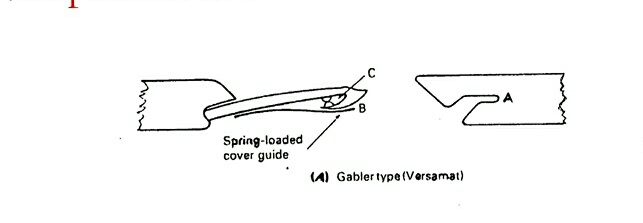

Relay nozzle are mostly at needle type or of oval shaped cross section to minimise the variation of the angle of jet axis with input air pressure .A confuser air guide is formed by fixing the individual lamellac together at uniform intervals .these lamels have nearly annular shape with a small cut at the top to facilitate the weft yarn to slip out of the confuser before beat- up.

Suction Funnel and Water Collecting Arrangement -

Suction funnel at the right hand side in air jet looms keeps the newly inserted weft intact, till it is beat- up into cloth . Collection of water used up for weft insertion in water jet looms is keep the loom shed dry and clean and also to save the water.

Weft feeler -

This system feels the presence of weft yarn by optoelectronic or photo electronic principle. Since these type of sensors reliability and service life are poor in water jet looms, Mechanical wire type are employed , which feel the presence of the weft after beating.

Air Distribution or Water Pumping -

Air is supplied to each loom by central compressor system . This system can cater a group of looms is fitted with suitable dryers and filters to provide dry,oil and dirt free air to looms .But in water jet looms water is pumped through a individual pump , which is driven from the main shaft .

Add diagram and sketches

ReplyDeleteFor reliable ground stabilization and erosion control, choosing a trusted provider is essential—especially when it comes to Geotextile Bags Singhal Industries Pvt Ltd. These bags are crafted from durable, UV-stabilized woven fabrics that provide excellent filtration and strength in demanding environments. Ideal for applications like shoreline protection, landscaping, and foundation reinforcement, they offer high load-bearing capacity with easy installation. Lightweight yet rugged, these geobags help reduce material and labor costs while enhancing structural resilience. Partnering with a reputable manufacturer ensures quality, performance, and longevity in your geotechnical projects.

ReplyDelete